Many factors have an impact on whether we feel comfortable in a room.

Like many other things, comfort also belongs to the merely subjective perceptions of a human. Volume, temperature, humidity, brightness – but also the social environment, the furnishing of lounges and one’s personal state of health have an influence on how we feel. An important aspect here is thermal comfort. Yet how do we define something that is so difficult to grasp? And how can thermal comfort be established?

Thermal comfort means in simple terms that the heat produced in the body is also released and this thus does not lead to overheating or cooling down. Now, the human body is able to produce heat in the range of 80W (basic load when relaxing) and about 800W when doing the most difficult physical work. It is thus worthwhile looking at the mechanisms available for releasing heat and at the other influential factors that have a hindering or favourable effect.

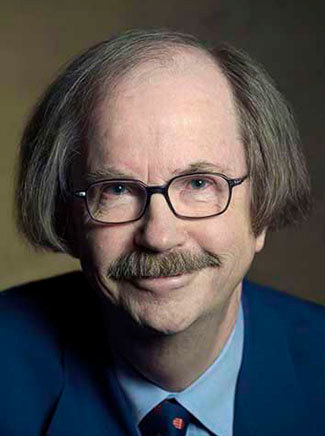

In the human body, heat is transported purely convectively through the blood. It is primarily released to the environment via the skin, but also as breath via the lungs. Whilst our breath only releases heat latently and sensitively, there is a large proportion of radiation via the skin and a small amount is directly released, for example, via the soles of the feet. Various factors of influence have an effect on these three essential release processes (convection, evaporation and radiation). First of all, this is the production of heat as a direct consequence of the respective activity. A further (human) influencing factor is the insulating clothing with a direct impact on all three ways of releasing heat. On the part of the environment, the air temperature and movement have a direct impact on the convective release of heat and humidity has an impact of the latent release by evaporation. The release in the shape of radiation, in contrast, is the difference between the radiation sent out and coming in and thus depends on the surface temperature of the surrounding surfaces. Back in 1970, Ole P. Fanger presented extensive studies on this cluster of topics in his doctor’s thesis at Denmark’s University of Technology (DTU) and identified the six influencing factors stated above as the significant ones.

OLE P. FANGER was a Danish engineer whose dissertation on thermal comfort counts among the most important papers in this sector.

THE STUDIES OF OLE P. FANGER

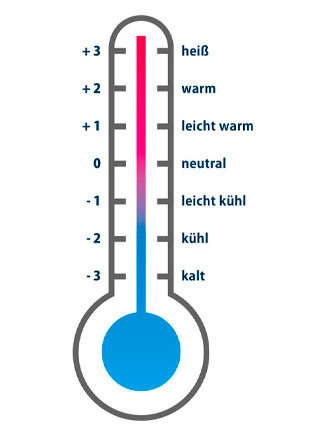

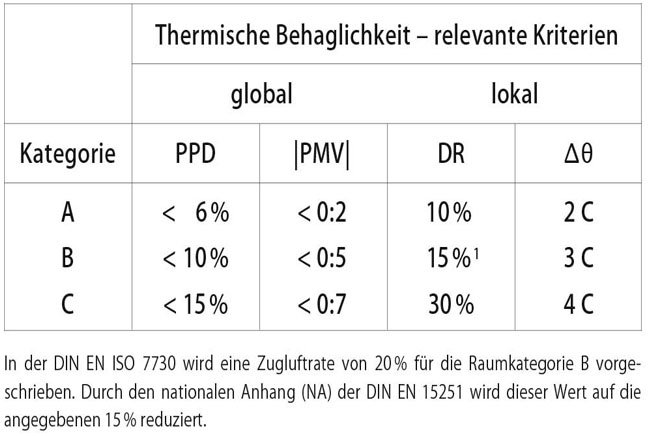

Fanger had normal workplaces set up in his laboratories at which his probands carried on with their normal activities in varying types of clothing. Fanger was able to set any room climate parameter. The probands had to rate their thermal comfort on a seven-digit scale from -3 (cold) to +3 (hot) at regular intervals. For each combination of the above influencing factors (activity, clothing, air temperature, humidity, air velocity, temperature of the surrounding surfaces), he was given a “mean vote” by the probands. He succeeded in deriving a mathematical formula: the Fanger equation. This correlates the six relevant parameters with the “mean vote”. For the climatic interpretation of rooms, this process is simply reversed: the planned use of the room is known and the users’ clothing can be predicted. Together with the environmental parameters, a “predicted mean vote” can be derived. Fanger had now classified and defined the probands’ vote that people were satisfied when their vote was -1 or +1. All the others were thus not satisfied. He then found a direct correlation between the “percentage of unsatisfied people” and the “mean vote”. If you also reverse this process, the result is the “predicted mean vote (PMV)” from the six influencing factors and then from that the “predicted percentage of dissatisfied (PPD)” of DIN EN ISO 7730. If we look at the standard more closely, it becomes clear that even in the case of ideal room conditions, 55 of all people were still unsatisfied. – in other words, they find it either too cold or too warm. By way of the DIN EN ISO 7730, rooms are divided into three categories by the permissible PPD index. The highest demands of Category A apply for rooms that are used by sensitive people (toddlers, the sick, etc.). Category B applies for normal offices, whilst Category C is meant to apply first and foremost for existing buildings.

LOCAL COMFORT CRITERIA

Besides the global comfort criteria relating to the entire heating balance, Fanger introduced another four individual criteria relating to regions of the body. On the one hand, this is the draught rate – DR – for unclothed body surface areas. It depends on the air temperature, air velocity and the degree of turbulence. In this case, it must be noted that the National Appendix (NA) of DIN EN 15251 tightens the draught rate DR = 20 % stated in DIN EN ISO 7730 for rooms of Category B. A further local comfort criteria is the temperature difference of the air at face and feet level. Depending on the room category (A, B, C) 2 °C, 3 °C or 4 °C are permissible in this case. The third criterion is the floor temperature, whereby it can only be applied for feet with shoes on. For Categories A and B, the permissible temperature range is about 19 °C to 28 °C. For Category C, it goes in both directions about 2 °C further. The fourth and last comfort criterion is the asymmetric radiation distribution. Hereby, a differentiation must be made between ceiling and walls on the one hand, and warm and cold on the other. These are thus de facto four sub-criteria which, depending on the room category, are to be observed differently.

MEASURING COMFORT

Nowadays, the comfort in a room can be determined by way of the most modern measuring technology as per DIN EN ISO 7730. For room air-technical systems to not negatively influence comfort, intensive research and development is being performed at Kampmann. Kampmann’s units generally have hardly any effects on radiation asymmetries or the floor temperature so that merely the PPD Index, the vertical temperature difference (Δϑ) and the draught rate (DR) are of significance. With the PPD Index, it means that the unit must be able to neutralise heat or cold loads that are drawn on in the interpretation, i.e. maintain the room temperature without there appearing to be a draught or air stratifications in the lounge. Whilst heating in a normal case is uncritical in this regard, cooling a room with trench heating systems is frequently a particular challenge. As cooled air cannot be blown out directly into room occupied due to creating draughts, they are to be installed as high as possible along the façade so that when the air drops, it mixes well with the room air and then slowly expands over the floor into the room. Unfortunately, this leads to a part of the cooled air being suctioned into the unit again; in this context, one speaks of a “short circuit”. Depending on the fan setting and water temperature, the share can be 40% and more, which leads to significant losses in performance. In Kampmann’s Research and Development Centre (FEC), besides the usual system parameters, the draught rate and temperature stratification are measured in parallel. All units by Kampmann are not only optimised in terms of performance but also in terms of comfort. Especially when it comes to special customer requirements in relation to furnishings, room geometries or layout requirements, the FEC offers the possibility to adjust every unit optimally to the respective use by way of its room air flow laboratory.