How Kampmann deals with the upcoming challenges – and opportunities

With the COP26 at the latest, “Net Zero Carbon Buildings”, “Decarbonization” and “Embodied Carbon” have become omnipresent buzzwords. We are all on the road to “Net Zero” – in our private life, as well as in our business life. As the built environment sector plays a vital role in the whole life carbon transition, the first step will be to design our buildings in a way that reduces energy consumption and maintains comfort with regards to fresh air supply, temperature and acoustics.

Arguably, the construction industry has seen more changes within the last year than the 20 years before. One of the most significant changes specifically in the HVAC industry is the publication of the CIBSE TM65, which focuses on the embodied carbon of HVAC products. The suggested embodied carbon calculation methodology for building services products, to be used where Environmental Product Declarations are not yet available, helps consultants understand the embodied carbon of the systems they design and the products they specify.

Another significant change is the updated carbon factors for electricity within the Part L 2020, which means an end to the use of fossil fuels for the thermal conditioning of our buildings – i.e., the days of traditional boilers are numbered. In the future, we expect our buildings to be cooled and heated based on clean electrical energy. The focus will be on reversible heat pumps / 4-pipe chillers, and for heating, also on the use of direct electrical heating. It is important to bear in mind that with modern buildings, the demand for heating our spaces will be minimized and for what little is still needed, direct electrical heating will be an option. Latest studies have shown, that for example within residential buildings, direct electrical heating may become one of the preferred options, when it comes to the embodied carbon of the products installed.

Manufacturers to be considered engines in responding to the climate emergency

From a manufacturer's point of view, the new product information for Life Cycle Assessment calculations is an enormous requirement. At stake is not only the collection of data for existing products, but also the question which materials manufacturers will use for future products. It is up to manufacturers and suppliers of materials and building products to develop and design a new generation of products that will enable architects and consultants to design their projects in such a way that the targets set in the Paris Climate Agreement can be achieved.

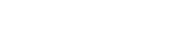

A specific example for the reduction in embodied carbon is the covering grilles of trench products. Today, these grilles are made of aluminium for most projects, as this is the most commercial option. On the other hand, from an embodied carbon point of view, the use of aluminium is particularly critical. Therefore, there are alternative materials for grilles available. Switching from aluminium grilles to stainless steel grilles reduces the embodied carbon content of the grille by about -30 %. Even more significant is the switch to a wooden/timber grille, which saves about -90 % of the embodied carbon of the grille.

At Kampmann, we are aware of our enabling role as manufacturers in shaping our Net Zero future, considering the current developments as an opportunity. One the one hand, we rely on cooperation when it comes to data disclosure. On the other hand, we commit to decarbonisation pathways, working on a new generation of products to meet both, the trend towards direct electrical heating and the reduction in embodied carbon.

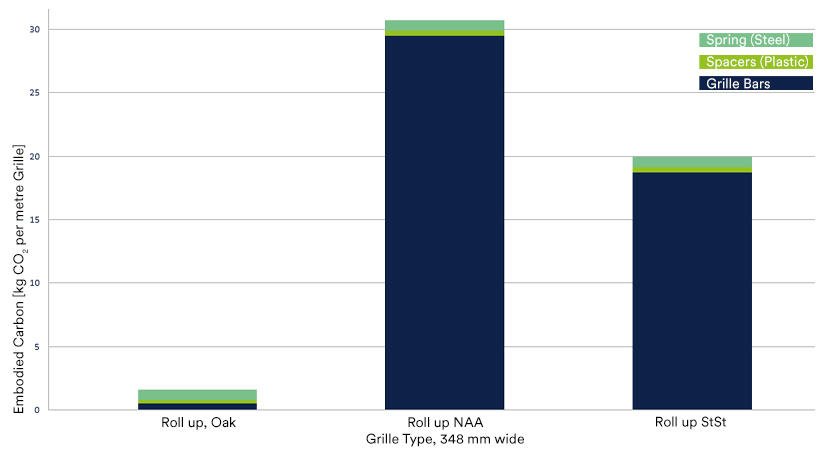

With our Katherm HK E, Kampmann has just launched a new generation of trench heating and cooling units that work with chilled water cooling and direct electrical heating, particularly suitable for the non-domestic sector, where MEP account for about 15 % of all embodied carbon of a building. Direct electrical heating from renewable, fossil free sources will be on the rise in the future for heating in net-zero buildings. Obviously, no LPHW pipe connections are needed, so all LPHW pipework in the floors and risers can be significantly reduced, if not eliminated. It is not just the pipework itself, but also the lagging, associated valves and actuators, as well as fittings and fixings. This has a direct impact on the embodied carbon calculation of the building, as a significant amount of material is not needed at all. In addition, units with direct electric heating do not require the same effort in commissioning as with LPHW heating. This all brings savings in installation time as well as cost savings due to the reduction of materials/components required and labour time. Thus, specifying Katherm HK E units leads not only to massive upfront carbon savings, but also contributes to moving towards a circular economy.

As materials are the main contributors of embodied carbon emissions from buildings, manufacturers must come up with new ideas and solutions that result in energy saving products. These products should use the correct components like up-to-date EC fans. Suitable materials should be selected to minimize the embodied carbon of the product itself. Manufacturers will also have to speak to their pre-suppliers. Where do the raw materials come from? How much recycled content is within this material? Through disclosure of the product-specific embodied carbon emissions, manufacturers are likewise enablers in respect of other actors in the value chain. Yet they cannot achieve the net zero targets on their own. They will require finance, supportive policy frameworks, and last but not least, adequate demand for their low carbon products.